| Model | DXTZ-3 | DXTZ-4 | DXTZ-5 | DXTZ-6 | DXTZ-7 | DXTZ-8 | DXTZ-9 | DXTZ-10 | DXTZ-11 | DXTZ-12 | DXTZ-13 | DXTZ-14 | DXTZ-15 |

| Cooling Capacity* (kW) | 12 | 18 | 25 | 35 | 50 | 65 | 80 | 100 | 120 | 140 | 170 | 220 | 260 |

| Rated Flow (L/min) | 100 | 150 | 200 | 250 | 300 | 350 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 |

| Max.Working Pressure (bar) | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Fan Power (kw) | 0.55 | 0.75 | 1.1 | 1.5 | 1.5 | 2.2 | 3 | 3 | 4 | 2*2.2 | 2*3 | 2*3 | 2*4 |

| Inlet&Outlet Thread | G1" | G1¼" | G1¼" | G1¼" | G1¼" | G1½" | G1½" | G1½" | G1½" | G2" | G2" | G2" | G2" |

| Thermometric Thread | G3/8" | G3/8" | G3/8" | G3/8" | G3/8" | G3/8" | G3/8" | G3/8" | G3/8" | G3/8" | G3/8" | G3/8" | G3/8" |

| Noise Level** (dB) | 62 | 66 | 68 | 75 | 77 | 80 | 83 | 87 | 92 | 85 | 86 | 92 | 98 |

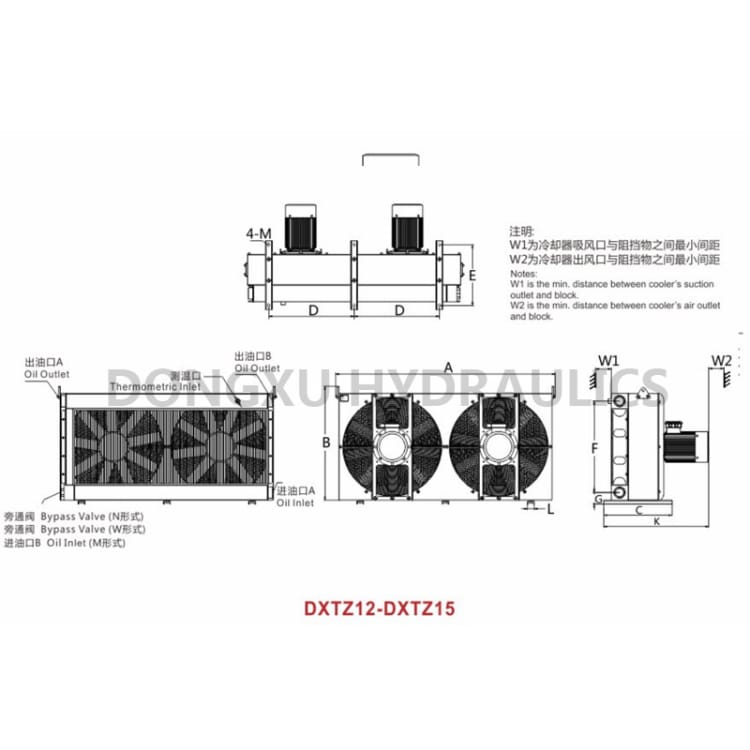

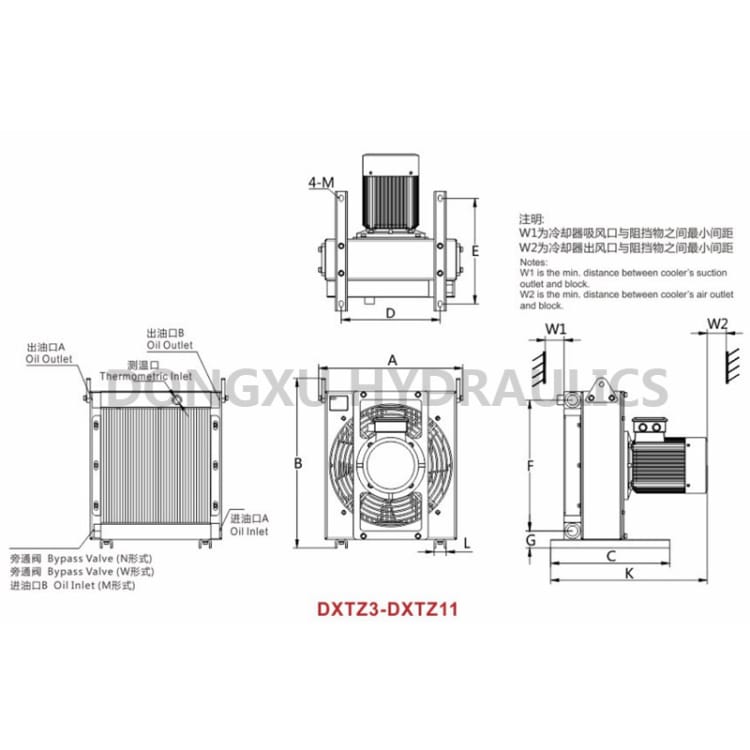

| A (mm±5) | 427 | 532 | 587 | 632 | 632 | 752 | 837 | 972 | 1082 | 1442 | 1642 | 1842 | 2047 |

| B (mm±5) | 503 | 563 | 603 | 623 | 623 | 763 | 919 | 1059 | 1208 | 763 | 913 | 1043 | 1193 |

| C (mm±2) | 350 | 350 | 350 | 450 | 450 | 450 | 500 | 600 | 600 | 450 | 500 | 600 | 600 |

| D (mm±2) | 290 | 390 | 450 | 490 | 490 | 560 | 645 | 700 | 700 | 560 | 645 | 700 | 800 |

| E (mm±2) | 310 | 310 | 310 | 400 | 400 | 400 | 450 | 550 | 550 | 400 | 450 | 550 | 550 |

| F (mm±5) | 384 | 434 | 475 | 495 | 495 | 634 | 780 | 920 | 1070 | 600 | 760 | 900 | 1050 |

| G (mm±5) | 50 | 55 | 55 | 55 | 55 | 55 | 60 | 60 | 60 | 75 | 70 | 65 | 65 |

| K (mm±10) | 496 | 530 | 535 | 611 | 631 | 656 | 686 | 686 | 713 | 706 | 706 | 706 | 713 |

| L (mm±2) | 40 | 40 | 40 | 45 | 45 | 45 | 55 | 55 | 55 | 45 | 55 | 55 | 55 |

| M (mm±2) | 12*18 | 12*18 | 12*18 | 12*18 | 12*18 | 14*22 | 14*22 | 18*25 | 18*25 | 14*22 | 14*22 | 18*25 | 18*25 |

| W1 | 180 | 200 | 220 | 250 | 280 | 320 | 380 | 400 | 500 | 320 | 380 | 400 | 500 |

| W2 | 380 | 400 | 450 | 500 | 550 | 650 | 750 | 800 | 1000 | 650 | 750 | 800 | 1000 |

| Note: * Cooling capacity: cooling power at △T=40℃. ** The noise value is measured at a distance of 1m from the cooler, which is only for reference. Because it is affected by the surrounding environment, medium viscosity and reflection. *** This table only takes AC380V-50HZ as an example. **** Motor grade: Energy consumption grade YE2, protection grade IP55, insulation grade F. (Other options please contact DONGXU) | |||||||||||||

Marine machinery

Drilling platform

Wind power

| DXTZ | 8 | C1 | A3 | 5 | N | C | X | O | O |

| Cooler Type: Special Environment Marine Motor Drive Series | Plate Size: 3/4/5/6/7/8/9/10/11/12/13/14/15 | Motor type: C1=Marine Three-Phase Asynchronous Motor⬅Standard C2=Marine Explosion-Proof Three-Phase Asynchronous Motor | Voltage: A3=AC380V⬅Standard A4=AC440V A5=AC660V | Frequency: 5=50Hz⬅Standard 6=60Hz | Bypass Valve: N=Build-in⬅Standard W=External M=Without Bypass Valve | Oil Hole Direction: C=Side in side out⬅Standard S=Up in up out | Wind Direction: X=Suction⬅Standard C=Blowing | Temp. Controller: O=Without controller⬅Standard T=Temp. Switches--Action Temp.: T50=50℃,T60=60℃,T70=70℃ C=Temp. Transmitter-- C1=Compact,C2=Digital | Heatsink Protection: O=Without protection⬅Standard S=Anti-Stone net |

Deck port machinery

Independent cooling circuit,Hydraulic system circuit and lubricating oil cooling system. For examples,ship machinery,marine machinery,deck port machinery,drilling platform,wind power equipment,and so on.

Ship machinery

DONGXU air-cooled coolers are divided into indirect, fixed and suspended types. It also has many features, its simple structure, small size, small weight and ease of use are all its advantages. Air-cooled oil cooler (referred to as air cooler) is an aluminum alloy plate-fin heat exchanger with air as the cooling source. The same volume is larger than the traditional heat exchange area, the heat transfer efficiency is high, and the air is used as the medium for heat exchange. Compared with the water-cooled radiator, it is not only easy to install and maintain, but also can avoid the oil-water mixing caused by the copper pipe burst, which will cause serious damage to the system. Secondly, for equipment (such as construction machinery) that needs to change the working location, there is no need to consider the supply of water sources, and there is no disassembly and reconstruction of the water circulation system. It is an environmentally friendly product that is increasingly widely used. DONGXU is one of the most credible special motor hydraulic oil cooler manufacturers and suppliers in China. Welcome to buy special motor hydraulic oil cooler with reliable performance with our professional factory.